Constructing an

impressive product

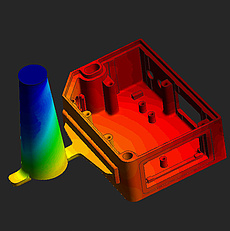

Turning ideas into functional and decorative die-cast parts is a challenge our engineering department responds to every day. Even the inspection of design specifications is always oriented on devising a trouble-free production process. Applying experience, finesse and the latest software and hardware, die-cast parts are engineered to meet the greatest possible demands. Precision die casting begins right from the design and engineering stage. Trial molds and making up sample parts serve to monitor the processes and set the way for perfect production.

Using the latest CAD systems and prototyping procedures - a 3D printer, for example - whips every part into shape and readies it for mass production. In this way all the phases of manufacture, including casting procedures and CNC machining, are simulated right in the planning phase.